What is Rapid Tooling & How Can It Accelerate Manufacturing?

Rapid tooling offers many unique benefits to the prototype and production stages for businesses that can help accelerate manufacturing.

The Advantages of Rapid Tooling & 3D Printing

What is rapid tooling? Rapid tooling through 3D Printing is an important process that can help you accelerate manufacturing. Rapid tooling can help you create high-quality tools quickly and inexpensively.

Rapid tooling is used in the prototype stages to test and validate the parts in the design. For production, rapid tooling can accelerate your time to market and is valuable in short run production situations.

Choose Rapid PSI as your Rapid Tooling Company and get started today!

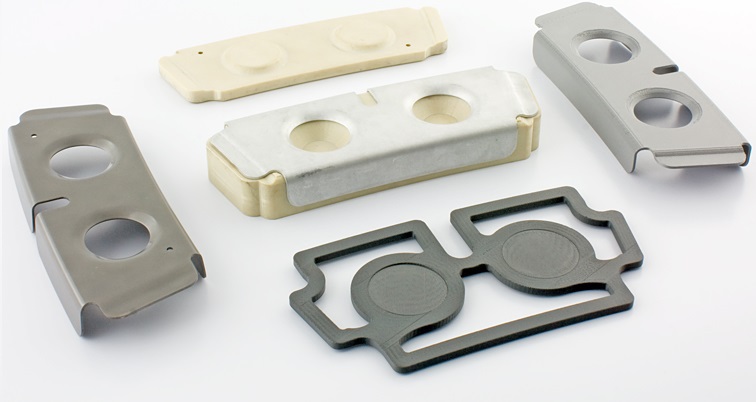

Types of Rapid Tooling

- Holding Fixtures

- Welding Fixtures

- Fiberglass/Composite Layups

- Routing Tools

- Vacuum Forming Tools

- Hydroforming Tools

Get to Market Faster

Rapid tooling can fill the gap between design and product manufacturing. 3D printing can create short run production tooling like layup, forming, and vacuum tools right from CAD data. These printed tools can produce a finished product to sell while high volume production tools are being manufactured.

Improve Manufacturing Processes

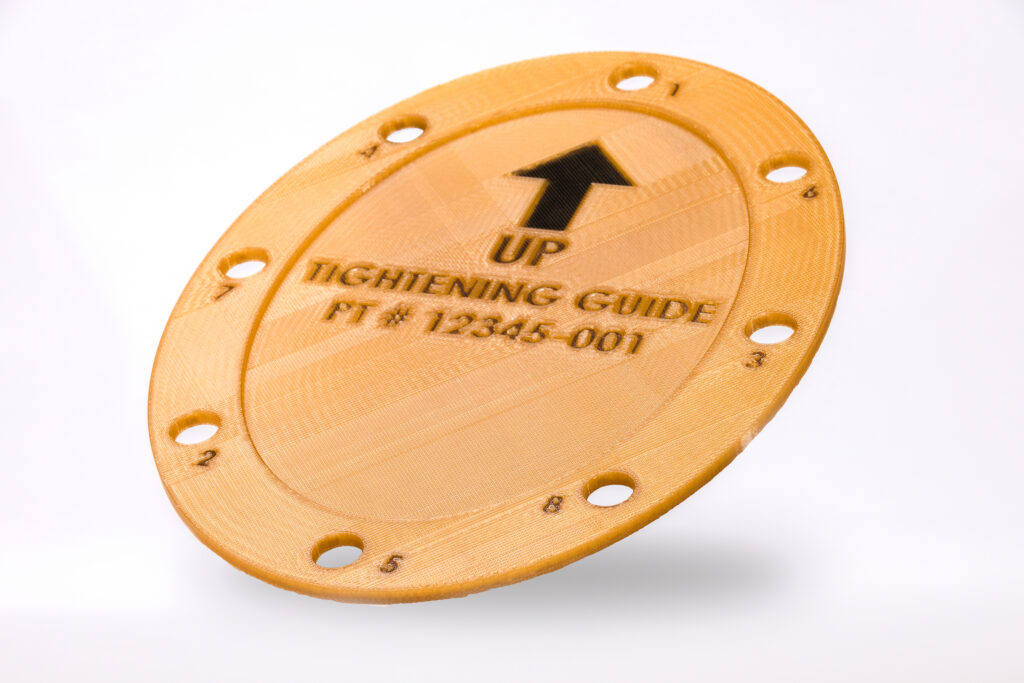

3D printing manufacturing tools is a quick way to improve processes in a manufacturing environment. Holding fixtures that are not cost effective to machine can be affordably printed and immediately implemented. Custom printed shadow boards increase organization and workflow. Go-NoGo tools are easily designed and printed to allow for continuous quality inspections on the manufacturing floor.

Variety of Materials

3D printing offers a wide variety of materials to choose for your rapid tooling application. Sometimes only high heat and strong surface is needed to form over. A Fused Deposition Modeling Ultem 1010 tool fits this rapid tooling application. The rapid tool can also be built with a honeycomb structure inside to save time, money, and weight while retaining the integrity of the surface to form over.

There are ESD materials available for anti-static clean rooms, high heat materials for elevated temperature tooling, and even chemical resistant materials to meet the highest demands.

Better Return on Investment

Setting up to do different kinds of manufacturing and prototyping will be an investment, but with rapid tooling, you will see an increased return on that investment. By reducing the development stage, you can start making sales faster and see an increase in revenue. With reduced development costs, this revenue will seem like even more and you will make up the money you spent in no time.

Because of the affordability of setup and the rapid return on investment, it is an ideal plan for businesses that have a limited budget to spend on production. It is also great for companies that are just trying to keep their operations in the black as much as possible.

Get Started

Rapid PSI is standing by to discuss your 3D printing needs. We are eager to help you understand our rapid prototyping services and how we can bring your ideas to life. With the power of 3D printing in our grasp, we can help you unlock new possibilities for your business or project. Let Rapid PSI be your trusted partner in the world of rapid prototyping.